Sanxin Technology

Sanxin abrasive manufacturing center is now one of non-woven grinding enterprises hitting the rapist development in China. Sanxin has been dedicated in research and development of non-woven abrasives for years. Sticking to be professional, we have developed to be mature and successful through great efforts. Our brand gradually becomes a leading brand. "Sanxin" brand has won special position in surface processing industry with its good performance. Sanxin has more than 1600 varieties enough to meet various demands of customers.

Product Advantages

Sanxin Product Advantages

Sanxin non-woven abrasives come into being with special fiber as basic material bound with grinding ore sands. Due to different grain size, variety and method of sticking to fiber, Sanxin abrasives have different functions, which can be used for clearing, deburring and other purposes. In addition, our products are complete in shape, variety and size, which can meet your different purposes and demands.

Advantages of Sanxin industrial abrasives :

*Even grinding force and even processing results

Owing to even distribution of ore sands on the fiber, when the surface layer is worn, new grinding velvet can immediately exert its function helping achieve even, smooth and graceful surface.

*High water resistance

Special fiber materials are resistant to water and oil.

*High plasticity

Good flexibility, suitable to all shapes of grinding charges.

*Dirt does not block grinding velvet joint

New velvet surface will be generated naturally after old grinding velvet is worn, hence dirt will not block the joints, keep the grinding surface always sound.

*Increasing surface adhesion of grinding charges

Grinding velvet will leave super minor traces on the article’s surface, which can increase surface real area, favorable for promoting adhesion effect of spray painting and coating.

*Controlled cutting

The grinding charges will not be extremely cut, hence avoiding bad products.

*Being rustless and no dropping

The product is safe and convenient to use and will not get rusted and dropped like wire brushes.

*Safe working environment

Noise, dust and error are taboos of safe working. Sanxin industrial abrasives feature in low grinding sound and little dust, providing users a comfortable working environment.

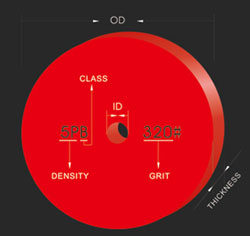

Parameter explanations

P-density Product density (hardness): 3P~12P, the larger the digital, the harder the product. B-grade Product model: generally three models: A, B, C 320# - grain size product grain size: roughness of abrasives, including 80# ~ 1200#. OD-outer diameter Product outer diameter: 50mm~600mm T-thickness Product thickness: common 25mm, 50mm, and other thickness available via customization ID-inner diameter Product inner bore, can be customized Speed conversion table

Diameter circumferential speed (m/minute) 15 20 25 30 35 40 45 Inch Mm rmp 1" 25 11500 15300 19100 23000 26750 30550 34370 2" 50 5730 7650 9550 11450 13400 15275 17185 3" 75 3825 5100 6380 7650 9000 10185 11455 4" 100 2865 3825 4775 5730 6700 7640 8600 5" 125 2300 3050 3800 4600 5300 6100 6875 6" 150 1900 2550 3200 3800 4450 5100 5730 7" 175 1635 2200 2730 3270 3800 4365 4910 8" 200 1440 1910 2390 2875 3350 3820 4300 9" 225 1275 1700 2100 2550 2975 3395 3820 10" 250 1150 1525 1900 2300 2675 3055 3440 12" 300 950 1275 1590 1900 2230 2550 2865 14" 350 820 1090 1370 1640 1900 2180 2450 16" 400 725 900 1200 1450 1675 1910 2150 Operating suggestions

(1) Meanings of common specifications

Non-woven abrasive products have many varieties and specifications according to different kinds, grain size and organization density (hardness) of abrasives.

Abrasive: generally corundum and silicon carbide; usually corundum is used for grinding metals and silicon carbide is selected for grinding hard and brittle materials or timbers.

Grain size: the larger the grain size, the higher grinding efficiency is; courser lines on the grinding surface result in lower finish and looser mesh fiber structure.

Organization density has influence on surface quality of work pieces: compared with lower density, higher density will result in clear lines, and the work piece is invulnerable to subjecting to inclined lines and breakage; with lower density, wheel sand texture is more consistent and it is also invulnerable to have the work piece surface burned.

(2) Some parameters during use of non-woven grinding wheels

The rotating speed of grinding wheels have influence on treatment results of work pieces and service life of sharper: when the work piece is made of hard materials and surface treatment effect is required to be excellent, high rotation speed is required, but with corresponding shorter service life; when the work piece is made of soft materials, low rotation speed is required, resulting in course surface treatment results.

Feeding speed also has influence on partial lines of work pieces: higher feeding speed leads to shorter time of partial cutting and fewer line segments; while lower feeding speed allows for longer time to treat partial lines.

Pressure when grinding wheel is grinding work pieces: higher pressure may lead to injury of burns and deform the grinding wheel; and lower pressure many cause unclear lines and low efficiency.

(3) Using environment

Non-woven grinding sheet can be used in water, oil or other corrosive, without worrying about rusting of wire balls and sand dropping of common sand paper. It can be used in combination of a backing plate or directly by hand. Use in humid environment may lead to decrease of product durability, so it shall be well protected from moisture during storage and use.

When there are high requirements on the surface, some lubricant can be used. Its heat radiation is effective, hence improving surface color and reducing dust.

When there are high requirements on the surface, some lubricant can be used. Its heat radiation is effective, hence improving surface color and reducing dust.

Rotation speed: it is an important fact which can influence processing effect, efficiency and service life of wheels. Actual speed shall be determined according to materials of work pieces and processing effect.

Rotation direction: winding wheel must rotate at the direction marked on the wheel side. And rotation direction of other wheels is not limited

Working pressure: generally light or medium degree pressure shall be imposed. Excessive pressure shall be avoided to protect wheel from deforming or damaging work piece surface.

Ventilation: generally ventilation may lead to unconscious lines and uneven work piece surface.

Work piece treatment effect Suggested line speed Finishing line 2.5-15 m/s Composite materials/soft sections 6-13.5m/s Surface cleaning 10-25m/s Final polishing pretreatment 10-32.5m/s Removing scales 25-32.5m/s Blending/polishing 30-40m/s Precautions

Safety precautions:

wear proper personal protective equipment (PPE) during operation.

NOTE:

PLEASE UNDER

THE PROTECTION

WHEN YOU WORKING!

1.Excessive fast rotating speed will lead to breakage of grinding wheel hence causing injury. The rotating speed shall not exceed the maximum limit marked on the grinding wheel.

2.It is required to remove flammable substances on the site and sparks shall not splash toward eye and body. During dangerous operation, workers shall wear appropriate mechanical protective cover to safely operate the product under direction of factory engineer (technician). When starting work, workers shall ensure that there is no person standing in the front or at the back of the grinding wheel. Incorrect use may lead to breakage of grinding wheels and cause injury.

3. of grinding wheels may lead to breakage and cause injury. It is forbidden to enlarge middle hole or change its shape, and wheels with gouge mark or laminated wheels shall not be used. In case of shaking or swaying during operation, the grinding wheel shall be stopped immediately. The breakage or swaying of the grinding wheels may be caused by below reasons: too large spindle; too tight screws; there are convexes on the edge of the wheel, or wheel edge is less than 1/3 of wheel diameter, or the diameter is not consistent and is bended.

4.Do not use or store grinding wheel under the ambient temperature >40 C°or<5 C°

Supporting the use of tools